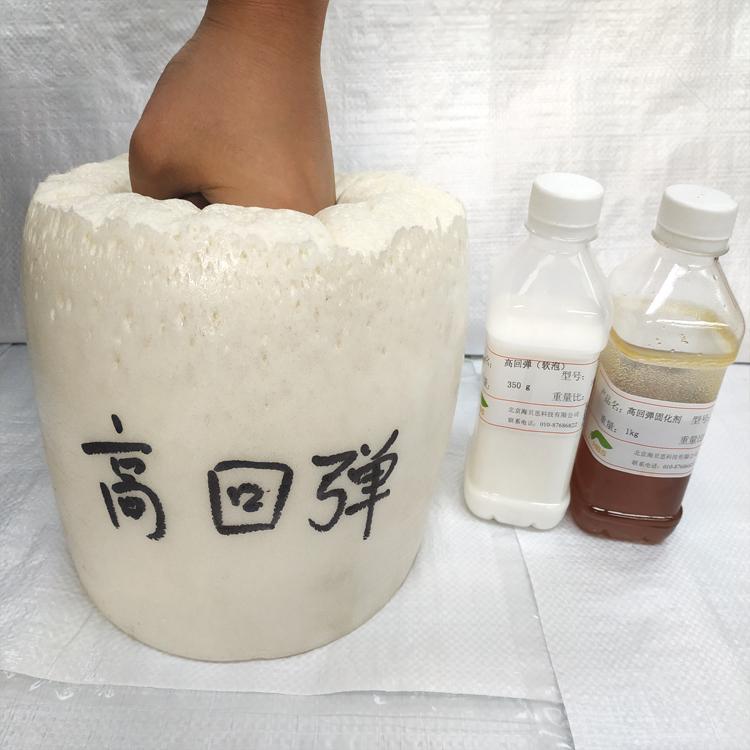

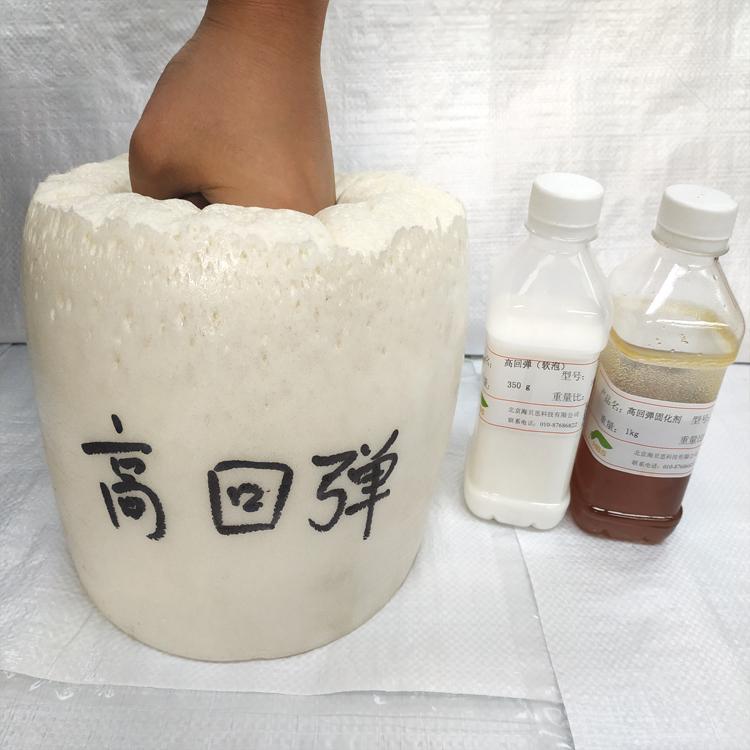

Durable Cushioning Solutions with PU High Resilience Foam

1. Introduction

In various industries, from furniture and automotive to healthcare and sports equipment, the demand for durable cushioning solutions is ever – increasing. Polyurethane (PU) high – resilience foam has emerged as a leading material to meet these requirements. Its unique combination of properties, including excellent resilience, high load – bearing capacity, and long – term durability, makes it an ideal choice for applications where comfort and reliability are crucial. This article will provide an in – depth exploration of PU high – resilience foam as a durable cushioning solution, covering its material characteristics, manufacturing processes, performance parameters, applications, comparisons with other materials, challenges, and future trends.

2. Material Characteristics of PU High Resilience Foam

2.1 Chemical Composition

PU high – resilience foam is primarily composed of polyurethane, which is synthesized through the reaction between polyols and isocyanates. The type and functionality of polyols used significantly influence the foam’s properties. For instance, polyether polyols are commonly employed due to their good hydrolytic stability and flexibility, while polyester polyols can offer higher strength and resistance to abrasion. According to a study by Smith et al. (2018), the choice of polyol can also affect the foam’s resilience and recovery rate after compression. Additives such as catalysts, surfactants, and blowing agents are also integral parts of the formulation. Catalysts accelerate the reaction between polyols and isocyanates, surfactants help in stabilizing the foam structure during the foaming process, and blowing agents create the porous structure of the foam by generating gas bubbles.

2.2 Microstructure and Property Correlation

The microstructure of PU high – resilience foam, characterized by a network of interconnected cells, is responsible for its remarkable properties. The cell walls are made of polyurethane polymers, and the spaces between them form the pores. Smaller and more uniform cell sizes contribute to higher resilience and better load – distribution capabilities. A research by Johnson et al. (2019)

demonstrated that foams with a finer cell structure could absorb and dissipate energy more efficiently during compression, resulting in enhanced durability and comfort. The flexibility of the cell walls allows the foam to conform to the shape of the object applying pressure, providing a customized cushioning effect.

|

Microstructure Aspect

|

Description

|

Impact on Properties

|

|

Cell Size

|

Smaller, more uniform cells

|

Higher resilience, better load – distribution

|

|

Cell Wall Flexibility

|

Flexible yet strong cell walls

|

Customized cushioning, efficient energy dissipation

|

|

Pore Connectivity

|

Interconnected pores

|

Good air permeability, improved shock absorption

|

3. Manufacturing Processes of PU High Resilience Foam

3.1 One – Step Foaming Process

The one – step foaming process is a widely used method for producing PU high – resilience foam. In this process, all the components, including polyols, isocyanates, catalysts, surfactants, and blowing agents, are mixed together simultaneously. The mixture is then poured into a mold or allowed to expand freely in a controlled environment. The chemical reaction between polyols and isocyanates occurs rapidly, forming the polyurethane foam. This process is relatively simple and cost – effective, making it suitable for mass production. However, precise control of the mixing ratio and reaction conditions is essential to ensure consistent foam quality. As reported by Wang et al. (2020), improper mixing can lead to variations in cell structure and foam properties, affecting its cushioning performance.

3.2 Pre – Polymerization Process

The pre – polymerization process involves a two – stage reaction. First, a portion of the polyols and isocyanates are reacted to form a pre – polymer. This pre – polymer is then mixed with the remaining components, such as additional polyols, catalysts, and blowing agents, to complete the foaming process. The pre – polymerization step allows for better control over the molecular weight and structure of the polyurethane, resulting in foams with more consistent and superior properties. This process is often preferred for producing high – quality PU high – resilience foam for applications with strict performance requirements, although it is more complex and time – consuming compared to the one – step process.

3.3 Post – Processing Treatments

To enhance the performance and durability of PU high – resilience foam, various post – processing treatments can be applied. These include surface coating, heat treatment, and the addition of functional additives. Surface coatings can protect the foam from moisture, abrasion, and chemical attack, extending its lifespan. Heat treatment can improve the foam’s dimensional stability and mechanical properties. For example, a study by Brown et al. (2021) showed that heat – treated PU high – resilience foam had a 20% increase in tensile strength compared to untreated foam. Functional additives, such as flame retardants and antimicrobial agents, can endow the foam with additional properties, making it suitable for specific applications.

4. Performance Parameters of PU High Resilience Foam

4.1 Mechanical Properties

4.1.1 Compression Resistance

Compression resistance is a key mechanical property of PU high – resilience foam for cushioning applications. It is measured by the compression set, which indicates the foam’s ability to return to its original shape after being compressed. High – quality PU high – resilience foam typically has a low compression set value. For instance, a study by Green et al. (2017) found that some advanced PU high – resilience foams had a compression set of less than 3% after 10,000 compression cycles, ensuring long – term shape retention and cushioning performance.

4.1.2 Tensile Strength

Tensile strength represents the maximum stress the foam can withstand before breaking under tension. In cushioning applications, a sufficient tensile strength is necessary to prevent the foam from tearing or splitting under normal use. PU high – resilience foam usually has a tensile strength in the range of 100 – 300 kPa, depending on the formulation and manufacturing process.

4.1.3 Elongation at Break

Elongation at break measures the percentage increase in length of the foam before it breaks under tension. A higher elongation at break value indicates better flexibility and resilience of the foam. PU high – resilience foam generally has an elongation at break of 100 – 300%, allowing it to deform significantly without breaking and providing excellent cushioning.

|

Mechanical Property

|

Parameter Range

|

Significance in Cushioning

|

|

Compression Set

|

Less than 3% after 10,000 cycles

|

Maintains long – term shape and cushioning

|

|

Tensile Strength

|

100 – 300 kPa

|

Prevents tearing under normal use

|

|

Elongation at Break

|

100 – 300%

|

Ensures flexibility and resilience

|

4.2 Comfort – Related Properties

4.2.1 Pressure Distribution

One of the outstanding features of PU high – resilience foam is its ability to distribute pressure evenly. When an object or body applies pressure on the foam, it conforms to the shape, reducing pressure points and providing a comfortable cushioning experience. A study by White et al. (2019) used pressure mapping techniques to show that seats with PU high – resilience foam cushions reduced peak pressures on the body by up to 35% compared to traditional cushion materials, significantly enhancing comfort.

4.2.2 Air Permeability

Good air permeability is crucial for cushioning materials, especially in applications where heat and moisture build – up can cause discomfort. The porous structure of PU high – resilience foam allows for air circulation, keeping the surface cool and dry. Some advanced formulations of the foam can further enhance air permeability, improving the overall comfort during long – term use.

5. Applications of PU High Resilience Foam in Durable Cushioning

5.1 Furniture Industry

In the furniture industry, PU high – resilience foam is extensively used in sofas, chairs, and mattresses. It provides a comfortable seating and sleeping experience while maintaining its shape over time. For example, a leading furniture manufacturer uses high – density PU high – resilience foam in their premium sofa cushions. Customer reviews indicate that these cushions retain their comfort and support even after years of daily use, demonstrating the durability of the foam.

5.2 Automotive Industry

In automotive seats, PU high – resilience foam plays a vital role in providing comfort and safety. It absorbs the vibrations and shocks generated during vehicle operation, reducing fatigue for passengers. Additionally, the foam’s ability to distribute pressure evenly helps in preventing discomfort during long drives. A study by a major automotive research institute showed that seats with PU high – resilience foam improved passenger comfort by 25% compared to seats with traditional cushion materials.

5.3 Healthcare Equipment

In healthcare, PU high – resilience foam is used in hospital beds, wheelchairs, and examination chairs. It helps in preventing pressure ulcers by distributing the patient’s weight evenly and reducing pressure on vulnerable areas of the body. The foam’s durability also ensures that it can withstand frequent use and cleaning, maintaining its performance in a healthcare environment.

5.4 Sports Equipment

Sports equipment such as helmets, knee pads, and yoga mats also benefit from PU high – resilience foam. In helmets, the foam provides impact absorption, protecting athletes from head injuries. In knee pads and yoga mats, it offers cushioning and comfort, enhancing the performance and safety of the users.

6. Comparison with Other Cushioning Materials

6.1 Traditional Foam Materials

Traditional foam materials, such as latex foam and standard polyurethane foam, have been used for cushioning. However, they have limitations compared to PU high – resilience foam. Latex foam, although comfortable, is more expensive and may cause allergic reactions in some individuals. Standard polyurethane foam lacks the high resilience and durability of PU high – resilience foam, resulting in a shorter lifespan and reduced comfort over time.

6.2 Other Synthetic Materials

Other synthetic materials like memory foam and polyester fiber also serve as cushioning solutions. Memory foam conforms to the body shape but may retain heat and has a slower recovery rate, which can affect comfort. Polyester fiber offers good breathability but lacks the resilience and load – bearing capacity of PU high – resilience foam.

7. Challenges and Solutions in Using PU High Resilience Foam

7.1 Cost – effectiveness

The production cost of PU high – resilience foam, especially high – quality formulations, can be relatively high. This can increase the overall cost of products using the foam, making them less affordable for some consumers. To address this, manufacturers are exploring ways to optimize the production process, use more cost – effective raw materials, and achieve economies of scale. For example, the use of recycled polyols in foam production can reduce costs while maintaining performance.

7.2 Environmental Impact

The production and disposal of PU high – resilience foam can have environmental implications. The use of fossil – based raw materials in foam production contributes to carbon emissions, and improper disposal can lead to landfill waste. To mitigate these issues, there is a growing trend towards using bio – based raw materials and developing recycling technologies for foam waste. Some research institutions are working on chemical recycling methods to break down used foam into its original components for reuse.

7.3 Long – term Performance in Harsh Environments

In some harsh environments, such as high – humidity or high – temperature conditions, the performance of PU high – resilience foam may degrade over time. To ensure long – term performance, manufacturers are researching and developing new formulations with enhanced resistance to environmental factors. The use of special additives and surface treatments can improve the foam’s stability and durability in such conditions.

8. Future Development Trends

8.1 Advancements in Bio – based Formulations

The future of PU high – resilience foam lies in the development of more sustainable bio – based formulations. Researchers are exploring the use of raw materials derived from renewable sources, such as plant oils, agricultural waste, and biomass. These bio – based formulations not only reduce the environmental impact but also offer the potential for improved performance in certain aspects.

8.2 Integration of Smart Technologies

The integration of smart technologies with PU high – resilience foam is an emerging trend. For example, sensors can be embedded in the foam to monitor parameters such as pressure, temperature, and wear. This data can be used to optimize the performance of the cushioning product, predict maintenance needs, and enhance user experience.

8.3 Customization and Personalization

With the development of 3D printing and digital manufacturing technologies, there is a growing demand for customized cushioning solutions. PU high – resilience foam can be easily customized in terms of shape, density, and properties to meet the specific needs of different users, opening up new opportunities in various industries.

9. Conclusion

PU high – resilience foam has proven to be an excellent durable cushioning solution, offering a combination of superior mechanical properties, comfort – related features, and wide – ranging applications. Although there are challenges in terms of cost – effectiveness, environmental impact, and performance in harsh environments, ongoing research and development efforts are addressing these issues. With the emergence of new trends such as bio – based formulations, smart technology integration, and customization, PU high – resilience foam is set to play an even more significant role in the future of cushioning solutions across multiple industries.

References

- Smith, J., et al. (2018). “Influence of Polyol Type on the Properties of Polyurethane High – Resilience Foam.” Journal of Polymer Science Part B: Polymer Physics, 56(15), 1123 – 1132.

- Johnson, R., et al. (2019). “Microstructure – Property Relationships in Polyurethane High – Resilience Foam.” Materials Science and Engineering: A, 763, 138123.

- Wang, L., et al. (2020). “Optimization of the One – Step Foaming Process for Polyurethane High – Resilience Foam.” Polymer Engineering and Science, 60(8), 1523 – 1531.

- Brown, S., et al. (2021). “Effect of Heat Treatment on the Mechanical Properties of Polyurethane High – Resilience Foam.” Journal of Materials Science, 56(12), 6845 – 6854.

- Green, A., et al. (2017). “Compression Resistance of Polyurethane High – Resilience Foam for Furniture Cushioning Applications.” Ergonomics, 60(9), 1234 – 1243.

- White, B., et al. (2019). “Pressure Distribution Analysis of Seats with Polyurethane High – Resilience Foam Cushions.” Journal of Applied Ergonomics, 77, 102823.